Pioneering Sustainable Coffee Roasting (That’s Us!)

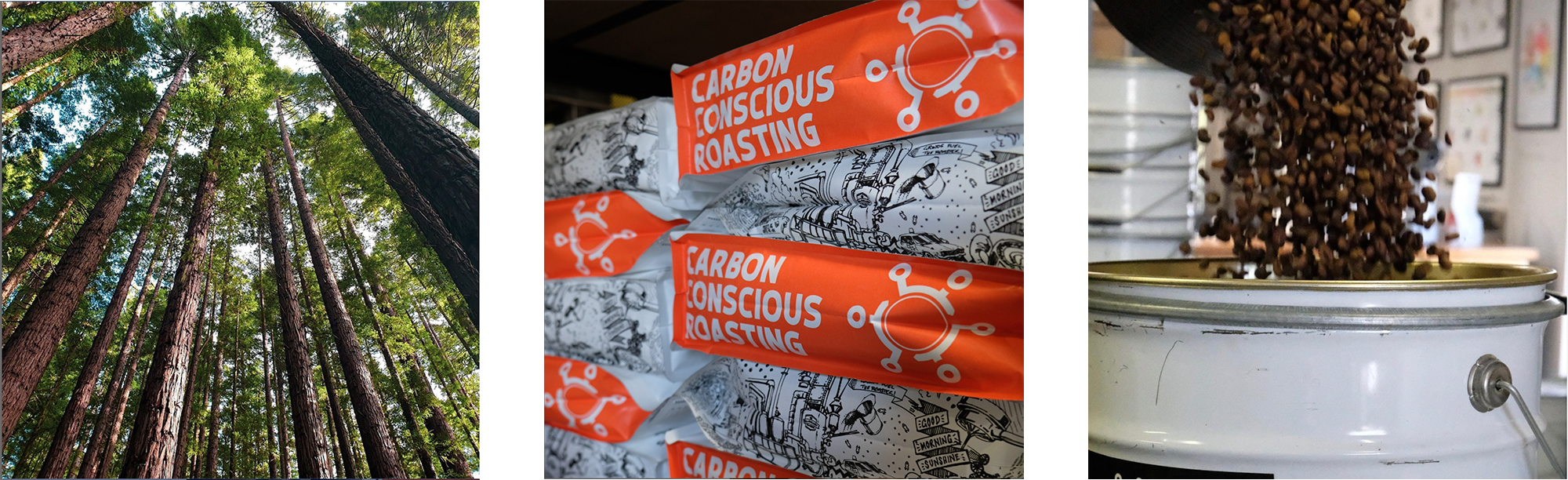

Do you want to know a dirty little secret of the coffee roasting industry? We'll spill the beans. Conventional commercial coffee roasters release heaps of nasty emissions into the atmosphere. They burn fossil fuels, producing hazardous gases like carbon dioxide and smoke containing carbon monoxide, air toxins, irritant volatile organic compounds, and nitrogen oxide. That's a considerable list of negatives, all for the privilege of your morning coffee cup. And so, because we couldn't imagine giving up coffee consumption, we worked hard to explore alternative options. There had to be a sustainable method of roasting green coffee beans to optimal flavour that makes us and the biosphere happy. Sprocket Roasters was soon born.

Not your typical barista-turned-coffee-roaster story, Sprocket’s founders are made up of a couple of hard yakka Aussie farmers turned chemical engineers, a viticulturalist with an MBA and a Canuk expat with a law degree. Drawing on our engineering and farming backgrounds, Sprocket roasts our sustainably sourced beans using innovative roasting technology that we designed, patented, and manufactured ourselves. The best part? Instead of running on fossil fuels, we fuel our roaster with bioenergy products, like that little puck of coffee you're left with after you've poured your shot and recyclable pellets. Our focus is to minimise environmental impact at the roasting stage as the bean travels from producer to cup.

We've got a down-to-earth crew here at Sprocket, but our carbon-conscious process is a world first in the coffee roasting industry and something we're not shy to be exceptionally proud of. We had a dream to build a business that combined a product we felt passionate about with a greener way of producing it. We quit our day jobs and, with the help of our incredible team, have been advocating the Sprocket way of roasting ever since. We’ve placed various medals at The Sydney Royal Easter Show, Melbourne Fine Food Awards, Australian International Coffee Awards, and Golden Bean Roasting Awards over the years. Sustainability isn't just another catchphrase around here; it has been the Sprocket way since we opened our doors in 2009!

From smoke to sustainability (a brief Newie history lesson)

Newcastle has a history of being the first and largest industrial city in Australia, dubbed "Smoke City" due to its steel manufacturing and coal exporting heavy industries. Over the last two centuries, smoke-filled skies were synonymous with Newie: the coastline that hosted visible air pollution. Therefore, perhaps it is ironic that Newie is also where we built the first clean-air commercial coffee roaster. And then again, maybe not.

For those unfamiliar with Newcastle's industrial past, precisely because of its heavy pollution, the city has pioneered smoke reduction measures in its post-industrial renaissance to slowly shift its industrial image to a cleaner, greener city. At Sprocket, our philosophy has been to continue building on this innovation and apply it specifically to the coffee roasting sector. We consistently endeavor to improve our processes to ensure we roast coffee in the most sustainable way possible. This industrious (albeit, sometimes anti-establishment) inventive streak is the Novacastrian way! We love our city and couldn’t imagine starting our roasting journey anywhere else.

Unveiling the operations (how it all works)

Our industrial-looking coffee roaster here at Sprocket might look like something out of a science fiction comic or maybe an episode of the 1960s classic The Jetsons (where we took inspiration for our name). However, the utopian future we’re most looking forward to is one that we have the agency to create ourselves. Here at Sprocket, we're doing our part towards the eco-just future we dream of, stemming from our two greatest passions: quality coffee and a healthy planet.

While most coffee roasters place great emphasis on sustainability practices that exist in green bean production, i.e., the country of origin’s farming initiatives (which is, of course, extremely important), they often fail to give attention to the significant environmental impact that happens in production here on home-turf (that dirty little secret we mentioned earlier).

Invented by chemical engineer John Winter and manufactured locally in the Hunter region, Sprocket has developed a fluid bed coffee roaster. Unlike conventional drum roasters (which work like a concrete mixer), we use air to move the beans around. By transferring the heat generated by combusting recycled hardwood pellets, coffee grinds, and other organic waste, we create our own fuel using an enclosed system that dramatically reduces emissions. First, the air passes through a heat exchanger and transfers the heat to the beans. Next, an added blast of cold air just before the hot air hits the beans. This process ensures precise temperature control to allow for an evenly roasted bean and the consistent flavour Sprocket Roasters are famous for.

Whereas conventional commercial roasters use afterburners to dispose of the chaff into the atmosphere, Sprocket’s coffee roaster captures this chaff instead and recycles it as fuel, resulting in near-zero emissions. The process is controlled by a programmable logic controller (PLC), an industrial computer. This means that we have roast profiles that go back years as an added measure of profile roasting to ensure consistency.

The patented technology has won recognition from Bioenergy Australia and the industry through The Australian Specialty Coffee Association (ASCA), not least a $64,000 Commercialising Emerging Technologies (COMET) AusIndustry grant and recognition at the Green Globe Australia Awards for Small Business Sustainability.

As a result, the coffee roaster significantly minimises incidents of over-roasting and reduces gas emissions with the careful reuse of exhaust gases. Running on bioenergy is gentler on Mother Earth and produces a superior quality product, time and again.

Sprocket’s journey: brewing sustainability and roasting excellence

We had this very futuristic coffee roaster. And that was on full display in our original café in Newcastle’s East End; we had to merge it with a 200-year-old historical site and somehow combine with all our mid-century modern vintage café furniture.‘Spacely Space Sprockets’ is the engineering/manufacturing firm in the vintage series The Jetsons. Our futuristic roaster resembles a rocket and is reminiscent of this much-loved 1960s space-faring family cartoon show. That’s how we landed on the name Sprocket. We’re a business grounded in family, and also in engineering, so the Jetsons theme resonated with us - somehow the concept all just came together organically!”

Our roaster was originally housed in Sprocket’s first café in Newcastle’s East End, on the corner of Hunter Street and Watt Street. The building was previously a bank and various other colourful businesses throughout its long tenure. Sprocket spent over seven years in this site but unfortunately had to vacate the café for redevelopment (all but the façade remains today, set to become a new apartment building). Being forced to find a new HQ, we settled on a warehouse in the centrally based Newie suburb of Lambton.

While it was a wee bit stressful at the time trying to find a new site and recommission our equipment in a very tight timeframe to continue coffee supply, in the end, our moving of locations was perhaps a blessing in disguise. We now have much more room to roast, repair machines and grow at our Lambton warehouse roastery and workshop. It has also allowed us the opportunity to fill the roof with a huge solar system as we continue to improve our sustainability initiatives. We’ve got fantastic neighbours and look forward to roasting coffee from this site for many years. Of course, this will never change the soft spot in our hearts for Newie’s historic East End, our original home.

Sprocket wants to show coffee drinkers that a greener, more sustainable way of roasting is possible. After all, we were (and still are) farmers first before stumbling upon this coffee-roasting gig! By using organic, end-of-life products to fuel the roaster, we are closing the loop at this stage of the industrial process by transforming material destined for landfill into input material for the next production stage. This circular economy reduces our consumption of resources and encourages us to look beyond the traditional way of roasting coffee, which hasn't advanced much in centuries. By learning from past methods and improving on them, we can ensure that all the Jetson families of the future can continue to enjoy their morning brew! (After all, Jane Jetson did love her coffee..."Rosie?!")

CARBON CONSCIOUS ROASTING